TimberSurf’s Model Railway

Modelling Tips, Links & Guides for Model Railways

Lumsdonia Railway

A web page for my indulgence and sharing ideas and irregular updates on my Model railway

SALE

PLUS

A guide to the many options to make your level crossing actually move!

Automation of level crossing Guide

Level Crossing (Gated)

Supply list

Plastic Level Crossing gates

2mm diameter brass rod (or slightly larger)

Brass tube slightly larger in internal bore than the brass rod

Electrical (Choccy block) connectors

1mm Piano wire (or 0.8 or 1.2)

SG90 servo

Mounting screws (see text)

Servo bracket (see Note 1)

Araldite (two part epoxy)

Servo controller (see Note 2)

An anatomy

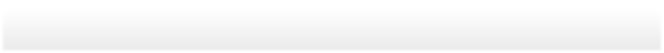

Here is my design to move the gates of a Level Crossing

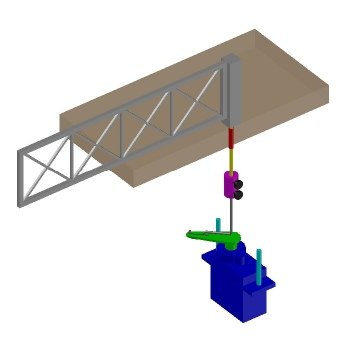

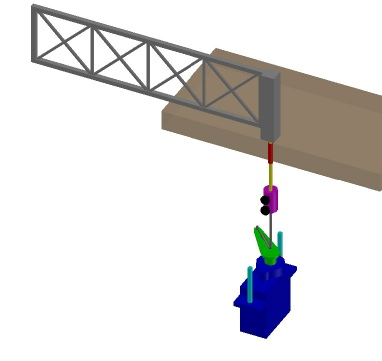

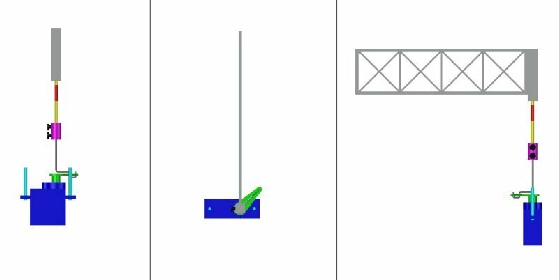

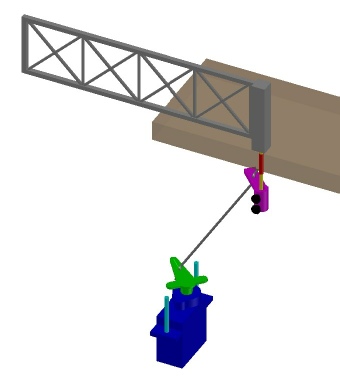

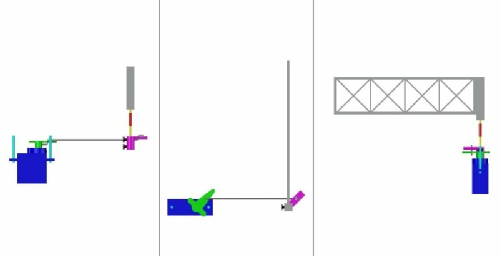

There are two designs, one for direct drive (I have called it Vertical) and the second is indirect (I have called it Horizontal) and is a little more low profile if space under the board is limited.

The Vertical design shown is for one servo per gate, but can be multiplied for two or four.

The horizontal design could be done with 2 or 4 servo's, but could equally be split into a tree of rods to drive all.

Instructions

Drill a hole up the gate post (grey)

Glue brass rod in (yellow)

Glue brass tube (red) into base board (brown), ensure it is at right angles in both directions

When set, drop the gate brass rod into tube with a plastic washer between to act as a bearing surface

Cut away plastic from one connector block to reveal the “two screw rod connector”

Attach to brass rod half way in, with one screw

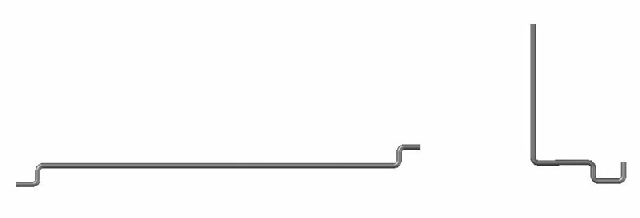

Bend piano wire (silver) to fit in servo lever (see pic below)

Attach servo to servo bracket

Assemble linkage (silver) to servo and offer up under board, mark mounting holes and affix bracket to board

Make final connection to “two screw rod connector” (purple) in the other side

Note 1

The servo bracket can be bought from MERG (v. 690 or h.681) or wooden (laser cut ply) {Ebay have a few offerings} or Peco, etc.

You can make your own from sheet brass/aluminium or wood

Or design your own and print in 3D

Note 2

Servo control can be bought from the likes of Peco, Megapoints, MERG, sometimes specific offerings from china on Ebay

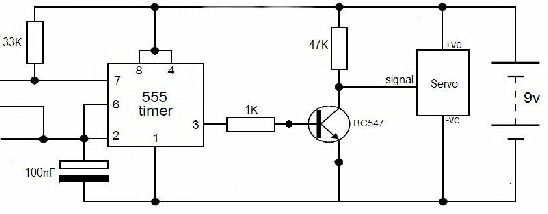

Or make your own with 555 timer or arduino or raspberry.

For the Horizontal “two screw rod connector”, a (similar size to servo lever) strip of brass is required, with holes drilled in a row, soldered to the brass boss

Here are the pic's of the design for the horizontal indirect drive type

Here are the pic's of the design for the vertical direct drive type

I have not actually built one yet, but it is loosely similar to other designs I have seen, that have been built, it's just they tend to be finished products that make it hard for the inexperienced to envisage how it's constructed. Hence I did the design in CAD, so that it is more understandable to all.

a. Any make of gate would work, most have a protruding bar that locates in a layout hole, the metal rod could be drilled up that or direct in the post if it were cut off.

b. I could tell you to use a Vee block and set with a spirit level, set on flat surface, with drill similarly positioned opposite, or put in a four jaw truck of a lathe and centre with DTI, or scan with 3D laser alignment tool and set point cloud data into CNC milling machine, but I won’t! Just do it by eye! :D

If the eye method gets it slightly out of true, it does not matter as the brass bar is easy to bend to bring it in line. Just make sure you start the hole in the centre, if it wanders off further in, a tweak with fingers or pliers will soon sort it out.

More importantly, it's imperative the (red) sleeve that it sits in, is at right angles (in two directions) to the surface of the layout. Best to glue the tube, with a plain rod in and support the rod with two square objects at right angles to each other) while it sets.

I am currently working on a magnetic coupling instead of the brass boss, so that accidental crashes will not harm the mechanism!

Having nearly completed a barrier type level crossing with flashing lights, I will soon write it up and add as a guide!

Design of wire for the horizontal indirect drive type

Design of wire for the vertical drive type

For those with a dilemma over driving the servo with home made/programmed (picaxe, rasberry, arduino, PC, etc.), there are several ready made circuits available like:-

http://www.blocksignalling.co.uk/index. ... riers-lcs5

https://www.heathcote-electronics.co.uk ... ssing.html

You could even build your own with a 555 timer circuit, but the easiest and cheapest for instant gratification, is to use a servo tester, most hobby shops have them or wait 6 weeks from china and much cheaper.

Back to HOW TO

Back to HOW TO