TimberSurf’s Model Railway

Modelling Tips, Links & Guides for Model Railways

Lumsdonia Railway

A web page for my indulgence and sharing ideas and irregular updates on my Model railway

SALE

PLUS

Idea’s to make your modelling life easier or better or cheaper

PROPERTIES - Section 600

Tips 600

Although many colours can be had, white LED’s come in several variations. They are specified by colour temperature, expressed as degrees kelvin (K), the higher the number, the whiter the light. Also sometimes quoted as a description:- warm, natural, day or cool.

Warm White - 2700-3500 Kelvin - typical incandescent light bulb

Natural White - 4000-4500 Kelvin - typical retail space "white" fluorescent lighting

Day / Daylight - White 5000-6000 Kelvin - used for high colour definition - typical noon day sun in many parts of the world

Cool / Commercial - White 6000-7000 Kelvin - used in many industrial and commercial applications like hospitals

I use Warm White , for my houses

I might go up to Natural white for offices/shop window etc

3mm Daylight for Mercury (inside engine shed) and 3mm yellow For sodium bulbs (street lights)

LED properties - Colour

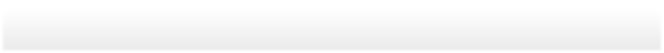

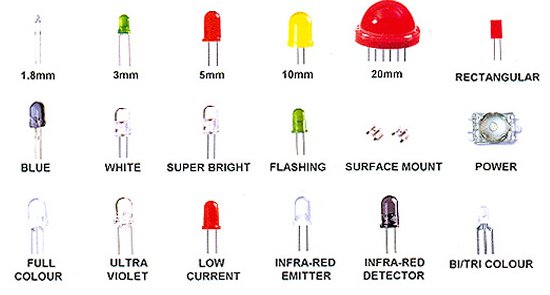

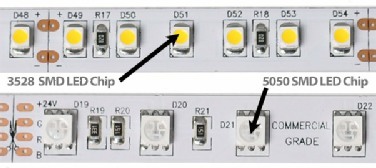

LED’s come in two main packages, “through hole” and “SMD” (Surface mount device). Each type has many sizes. Most can be had in the full set of colours. Some come in various angles of illumination (spread of light). Some clear lens give out coloured light.

LED properties - Size

If your rolling stock is too light, potentially long trains can derail on tight corners. The NMRA has a recommended practice that defines a practical weight for rolling stock. It is by no means a definitive standard, but is very useful as a guide, to getting more reliable running by weighting your rolling stock. It interprets in OO to about 30g for the initial weight plus 15g for each 25mm of the wagon/carriage.

Wagon example = 115mm long (roughly 4x25 + 12.5)

So 30g + 67g (4.5 x 15g) = 97g (100G)

Carriage example = 280mm long (roughly 11x25)

So 30g + 165g (11 x 15g) = 195g

Wagon length should be taken from the end of the couplings, weights should be distributed evenly and be the same either side of the middle point.

Use a small digital weigh scale to determine the weight of the wagon, then subtract from the calculated weight, the remainder is the weight that needs to be added.

Rolling stock running weight

Tip 603

SMD type can be had in strips up to 5 meters long, driven by 12V, these are handy for work area lighting and come in two types of SMD size (and in waterproof versions) with either 150, 300 or 600 lights per 5 meter.

Steer clear of superbright and 40mA and higher types as these will be too bright to be realistic on a layout (OK for task lighting)

Having glued together a filter and airbrush holder tube into a jar lid, to act as my homemade airbrush cleaner, it worked well, but several days later has started to fall apart!This means that I have discovered an interesting nugget of information! I use white spirit to clear the airbrush, and the mist coats the whole of the inside and the remainder does not evaporate. Thus the vapour has been attacking the hot melt glue I used to glue everything together.The glue goes very gooey and releases its bond on the substrate. I am not sure if the constant vapour is the trick, but I guess that a repeated application onto hot melt (that is not contained by a jar) may do the same over a period of time. Knowing that you can "undo" hot melt glue with heat, I thought it may also be useful to know that White Spirits is a solvent that can soften hot melt glue and allow its removal from a surface.

White Spirit dissolves Hot Melt Glue

Tip 612

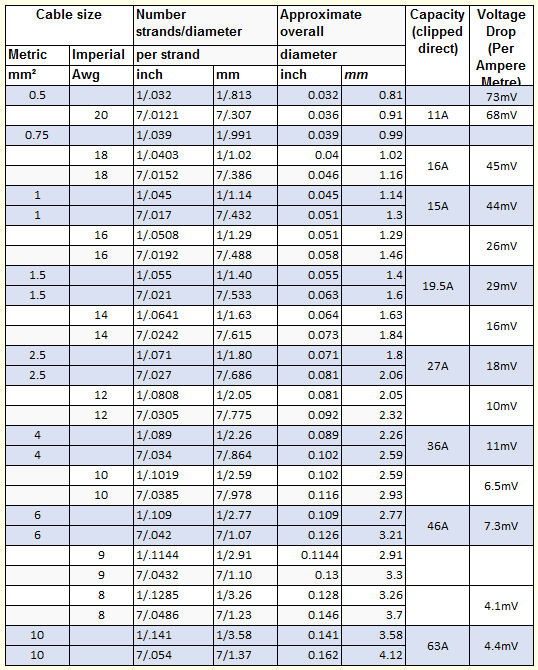

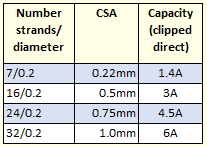

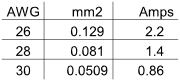

This chart is only a guide, cable calculations take a number of factors into account, not shown here. Generally use 7/0.2mm for short droppers and led’s and 16/.02 and larger for everything else.

See TIP202 for more info

Wire sizes/capacity/resistance

Tip 604

HomeReturn to top of pageBack to TIPS

HomeReturn to top of pageBack to TIPSSee here for Rail size and resistance

The usual formulation of nickel Silver is 60% copper, 20% nickel and 20% zinc

So 40% of it is only 25% as conductive as copper (60% + [25% of 40%] 10% = 70% of copper)

Material IACS (International Annealed Copper Standard)

Ranking Metal % Conductivity:-

1 Silver (Pure) 105%

2 Copper 100%

3 Gold (Pure) 70%

4 Aluminium 61%

5 Brass 28%

6 Zinc 27%

7 Nickel 22%

8 Iron (Pure) 17%

9 Tin 15%

But the cross section is smaller than you think, so Code 100 rail is equivalent of less than a 7/02, 0.22mm!!!!!!!!

My layout is going to be big, I need at least 1.5mm CSA wires! Trust me, I am an Electrical Design Engineer and have done the voltage calculations!

On a large layout (20-40ft) from one end to the other with worst case scenario, I have calculated it at 5 volt drop from one end to the other! Not including loads of bad electrical connections through the fishplates!

Hence a copper bus of thick wire is essential for larger layouts.

Nickel Silver track

Tip 605

Track rails will expand with heat!

If you have an indoor layout, the house temperature should be fairly regulated, so it will not be a problem. But if your layout is to be outdoors or in a garage, it may suffer issues!

Worse, if its in an attic/loft, an enclosed unregulated (temperature) space, then it can be worse than outdoors, but not quite as bad as outdoors in direct sunlight!

Techie babble - The coefficient of thermal expansion for Nickel Silver (alpha) is approximately 16.2 x 10-6 x the temperature delta, in degrees C

If we assume the worse of a latitude from 0°C to 40°C ambient, then:-

0.0000162 x 40°C = 0.000648, thus for 1000mm, it will expand 0.648mm

Even at an extreme of -10°C to 50°C (60°C delta), it will only be 0.972mm, so less than 1mm

If it is assumed that the ambient temperature is at 20°C and no gaps are left between the rails, if it gets hotter, the track will expand and with nowhere to go, so it will buckle! If it gets cooler than 20°C then the track will shorten and leave gaps between the rails.

You could wait until it is -10°C the fit with maximum gaps, but it is unlikely you would! So to is it unlikely to wait until it hits 50°C and fit with no gaps!

S o it is best to note the temperature when you are laying track and allow a little compensation. A 1mm gap every meter would be fine. If it is very cold you might use 1.5mm, or if warm say 0.5mm.

o it is best to note the temperature when you are laying track and allow a little compensation. A 1mm gap every meter would be fine. If it is very cold you might use 1.5mm, or if warm say 0.5mm.

Don't be tempted to overdo it! Train wheels don't like big gaps!

If your trains have an issue with wide gaps, consider offsetting the two rail joints slightly

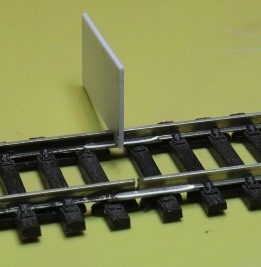

You can set the gaps with a feeler gauge, any material will do as long as it is a known thickness, if you can't measure it with a Vernier, use a known thickness sheet material like plasticard. 20 thou' card is 0.5mm and 40 thou' card is 1mm.

Bare in mind that points and crossover rails can not move, as they are fixed at the frog, unlike set track and flexi track that can slide within the chairs