TimberSurf’s Model Railway

Modelling Tips, Links & Guides for Model Railways

Lumsdonia Railway

A web page for my indulgence and sharing ideas and irregular updates on my Model railway

SALE

PLUS

How do you decide what underlay to use or not on your Model Railway?

The great Cork debate

Underlay

Are you about to lay track? Undecided if you should use cork, foam or nothing? Then read on for some interesting insights that might make you change your mind!

There are definitely two camps! Those that want to deaden track sound and those that advocate laying direct on the baseboard as they WANT the roar of the stock deafening the room! If your the later and don’t want sound loco’s, you need not read further!

When I was about to start laying track, I thought I would do some research into methodology's, as I will be running "Sound" on this layout. If I ignore the old "I want my trains to be noisy" brigade who advise track direct to the board and I want the least noise from the track, so I can hear my sound loco’s, I foresaw a problem, as I have 6mm ply as my top and it is very "reverberant", I need to deaden the running sound.

My research leads me to several new conclusions, all against my ‘old school’ experience!

A solid baseboard adds mass to deaden sound (run trains on some concrete and there is little noise!), you can add wood underneath the baseboard. along track path, (or add rubber foam below baseboard) as it helps deaden sound and give mass to the board to help reduce noise (it could be done as a later addition)

I found a video of a test of various underlay's with a sound meter, the results are interesting. No underlay gives the most noise, cork does reduce noise and foam reduces it slightly further! (Here is one of the less tecky ones)

But that is NOT the full story!

There are many other factors that impact the perceived sound.

If your board is 6mm ply with little support, it will reverberate like a drum! If you use one inch thick ply, the thick mass will deaden the running sound.

Hornby soft open cell foam disconnects the sound from the board, but then allows the track to reverberate itself, which actually amplifies higher pitch sound! (It is also rotted by UV over time and disintegrates!)

Cork underlay does not absorb sound, it is too dense and simply "connects" track "Acoustically" to the board. Even Depron/Plastizote foam or wood floor underlay, do similar, but not quite so badly.

Do not use track pins, as they too connect track "Acoustically" to the board, they will defeat the use of underlay. Glue the track to foam.

Dont use PVA glue for ballast! It makes a solid rigid mass that connects the track to board (side gravel touching board defeats the foam). Use Copydex diluted with water and meths/IPA. (stays flexible when set)

You can however glue foam to board with PVA (does not move over time)

Attach the track to the foam, with spots of Evostick (holds track in position, even when wetted, when ballasting)

Use diluted Copydex for ballasting (potential can allow track to move over time but Evostick spots will stop this)

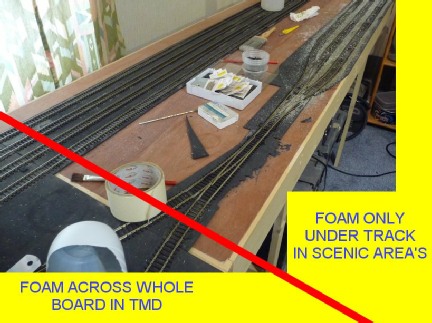

Many are less concerned about noise and simply use underlay to create the prototypical ‘shoulders’ , bare in mind TMD and shunting yards tended to be flat. I buy 1200x800x3mm closed cell foam sheets from numerous sources on the net.

So what is the answer, I hear you ask?

Well put simply, there is no definitive one. It depends on your baseboard construction/materials and ultimately, even with the best care and methods, the resultant difference is very small.

All I can do is to give some pointers:-

No underlay will result in more noise than having some

Don’t defeat the point of using underlay by reconnecting the track to the board with track pins or a solid lump of PVA (glue and hold with weights or use pins then remove them when dry)

Use the thickest board you can to deaden sound

If you use thin board, ensure the framing is not wide, add more wood or sound deadening foam to the underside of were the track is.

Closed cell foam is slightly better than cork.

The faster you run trains, the more noise they make, so if you have a small shunting layout, noise is not an issue! (Only huge layouts with fast expresses or small tail chasers with 100MPH peckets will create a din)

Code 75 and below may need a shoulder creating, but Code 100 is deep enough on it’s own without an underlay

New page